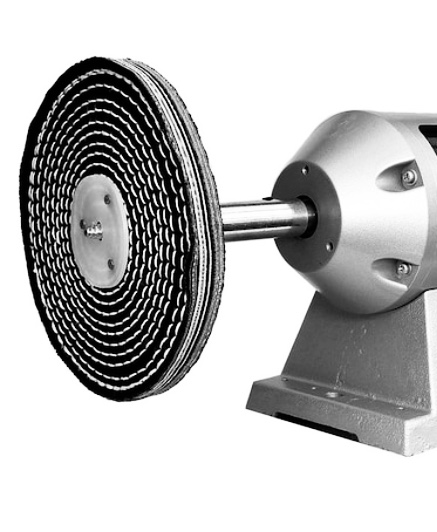

This is a great way of applying a protective low friction coating to individual parts. The parts can then be further lubricated with oil or grease as needed. An effectively burnished Wolfblood coating will be just half a micron thick and chemically fixed to the substrate. To burnish effectively a polishing mop fitted to a bench grinder or Dremel multitool is needed although burnishing Wolfblood by hand is possible.

SAFETY FIRST

Burnishing can be a messy process and will generate dust and fumes. Always wear suitable protective gloves, a mask certified to at least N95, good eye protection and protective clothing such as overalls. Heat will be generated and so be careful of burns and fire hazard. Isopropyl alcohol must be used with care and is itself a significant fire hazard.

REQUIREMENTS FOR BURNISHING WITH WOLFBLOOD

Dependant on the size of parts that are being burnished, make sure you have enough Wolfblood additive to coat the polishing mop, probably a few times. Isopropyl alcohol is required and is readily available from hardware stores and online. Again depending on the job 100ml to 1 litre is a good size to have in the workshop. An alcohol resistant mixing cup and stirrer are also needed.

HOW TO BURNISH WITH WOLFBLOOD

In a mixing cup blend Wolfblood with enough isopropyl alcohol to make a thick paste. Apply this paste to the polishing mop and allow to dry. Ensure that parts to be burnished are clean and free from grease, oil and dust. Once the mop is dry use it to polish to the parts vigorously. Much depends on technique here and practice makes perfect. The effectiveness of the bond is dependant on the Wolfblood being forced deep into the microscopic pits that exist on surface of the parts and adhering chemically to the substrate.

A few applications maybe needed – make sure everything is cool before applying more paste to the mop (wet the cup again with alcohol if needed) and again allow the mop to dry before resuming.

It should be quite clear which areas WB has been applied to as it will visibly darken the part. However judging when the coating is effectively bonded is harder to do. To test the coating wipe off any excess with a clean, lint free, cloth and then push a piece of clear sticky tape onto the part. The tape should lift away cleanly leaving the part still darkened and no marks.

CAUTIONS WHEN BURNISHING WITH WOLFBLOOD

Burnishing with Wolfblood generates heat, dust and flying debris. Observe safe working. The process will probably generate some sulphur fumes from the Wolfblood. This is normal but be aware that many sulphur gasses both smell bad and are bad for your health. Ensure adequate ventilation and again always wear a good mask rated to at least N95.

NOTES ON BURNISHING

Burnishing is essentially very vigorous polishing, that effects the substrate surface. While not quite as effective as coating using dry blasting it is a good technique for producing a durable coating quite easily with minimal equipment. We have more on the science here.